Most Popular Products

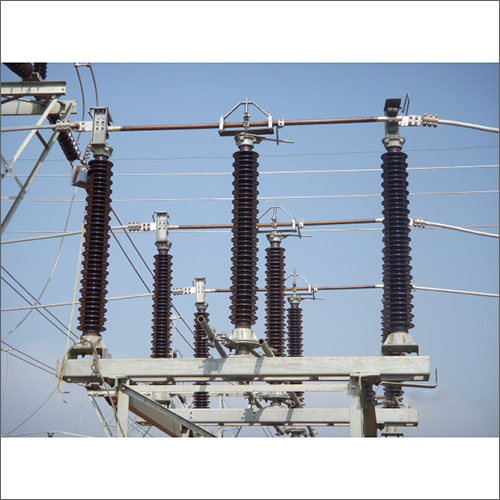

Substation and Transmission Tower

Price 115 INR/ Kilograms

Substation and Transmission Tower Specification

- Product Type

- Substation & Transmission Tower

- Material

- Mild Steel / High Tensile Steel

- Welding Standard

- IS 9595 / AWS D1.1

- Capacity

- 50 MT to 250 MT per Month

- Application

- Electrical Power Transmission

- Galvanization Standard

- IS 2629 / ASTM A123

- Out Coating

- Hot Dip Galvanized

- Standard

- IS 2062 / ASTM A36

- Shape

- Lattice / Angular / Tubular

- Surface Treatment

- Corrosion Resistant

- Height

- Up to 85 Meter

- Voltage

- Up to 765 kV

- Design

- Customized / As Per Client Requirement

- Thickness

- 3 mm to 20 mm

- Color

- Silver

Substation and Transmission Tower Trade Information

- Minimum Order Quantity

- 10 Metric Ton

- Supply Ability

- 300 Per Day

- Delivery Time

- 10-30 Days

About Substation and Transmission Tower

We are commercializing in an outstanding assortment of top-grade standard Substation and Transmission Tower. They are used in many industries for supporting overhead power lines. The Towers are structured using the best quality materials and up-to-the-minute techniques. They have a rugged configuration, the ability to function for an adequate time period, and are highly dependable. The Substation and Transmission Tower assists in moving the electrical energy from the generating place to an electrical substation.

Robust Structural Design for Extreme Conditions

These towers feature a superior lattice, angular, or tubular shape constructed from mild or high tensile steel, meeting IS 2062/ASTM A36 standards. Wind resistance up to 220 km/h and optional seismic reinforcement enable reliable performance in challenging environments. Surface treatments and smooth, zinc-coated finishes guarantee long-term abrasion and corrosion protection.

Flexible Assembly and Installation

Designed for straightforward on-site assembly with supplied nuts, bolts, templates, and bundled or crated packaging, our towers ensure rapid deployment. The knocked-down delivery condition simplifies logistics, while tailored foundations (concrete, pile, raft) allow adaptation to geotechnical conditions, minimizing installation delays and costs.

Comprehensive Customization and Longevity

From voltage capacity up to 765 kV to tower heights reaching 85 meters and shape choicesevery tower is engineered to client specifications. Anti-corrosive treatments result in low maintenance and extended durability, with a service life exceeding 25 years under standard operation. Accessories such as platforms, insulator brackets, and earthing enhance functionality.

FAQs of Substation and Transmission Tower:

Q: How are substation and transmission towers assembled on-site?

A: The towers are delivered in a knocked-down condition and are assembled on-site using provided nuts, bolts, and precise templates. This modular approach facilitates efficient installation while ensuring the structural integrity of the final assembly through either bolted or welded joints.Q: What are the advantages of the hot dip galvanized coating?

A: Hot dip galvanization to IS 2629 / ASTM A123 standards offers a resilient, zinc-rich coating that enhances corrosion resistance, extends service life, and ensures smooth, burr-free surfaces. This finish reduces the need for frequent maintenance even in harsh environmental conditions.Q: When is a specific foundation type (concrete, pile, raft) chosen for a tower?

A: The foundation typeconcrete, pile, or raftis selected based on site-specific geotechnical assessments. Factors such as soil type, load requirements, and seismic activity influence which foundation will provide optimal stability and longevity for the transmission or substation tower.Q: Where can these towers be used, and what voltage capacities are supported?

A: These robust structures are suitable for use across India and international locations in electrical power transmission applications, supporting voltages up to 765 kV. Their customizable design and configuration enable use in diverse climatic and topographical settings.Q: What benefits do anti-corrosive treatments provide in these towers?

A: Anti-corrosive surface treatments, including hot dip galvanization and smooth finishing, are crucial for minimizing degradation from environmental exposure. This results in low maintenance costs, enhanced safety, and a service life exceeding 25 years under normal operating conditions.Q: How is wind and seismic resistance incorporated into the tower design?

A: Towers are engineered to withstand wind speeds up to 220 km/h and can be customized for seismic resistance according to specific site requirements. The design uses lattice, angular, or tubular shapes and robust materials to provide structural integrity during extreme environmental events.Q: What accessories and customization options are available with your towers?

A: Every tower can be equipped with necessary accessories such as earthing systems, ladders, platforms, and insulator brackets. Additionally, clients can specify tower height, shape, material (mild or high tensile steel), and finish, ensuring every projects technical and aesthetic requirements are met.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

POWER LINE ACCESSORIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry